Secure of Supply

Reliable and Certified supply chain

In the defense industry, reliability is everything. Kiwa is an approved, independent body ensuring that your supplies, components and equipment meet the strict requirements defined by national and international defense organizations.

Organizations active in the defense sector are looking for optimal reliability of their products and supplies and need to be able to rely on optimal functionality of their supply chain. For this reason all components within the supply chain need to be assessed by approved organizations.

Kiwa offers services related to materials and products, personnel and processes, training of personnel and quality management consultancy. We provide our Testing, Inspection and Certification (TIC) services on standard certification norms such as:

In addition, we provide a comprehensive portfolio of complementary services that are equally critical to quality, compliance, and performance. These include the calibration of manufacturing equipment, testing of materials, components, and finished products, as well as the qualification and approval of welders, among others.

Depending on your organization’s needs, any of these services can form an integral part of a broader gap analysis, helping to identify risks, ensure conformity with applicable standards, and support continuous improvement across your operations.

Grow quality with our gap analysis

At Kiwa, we know that quality in the defense sector goes beyond internal processes. It extends across the entire supply chain, from OEMs and their suppliers to contractors delivering critical infrastructure for end users. Our gap analysis services support organizations in strengthening quality at every level, ensuring that products, processes, and partners consistently meet demanding requirements for reliability, compliance, and performance.

We help OEMs improve the quality maturity of their suppliers, particularly when new suppliers are introduced or when specific customer requirements are unfamiliar to them. Whether this involves implementing international standards such as ISO 9001, ISO 27001, NATO AQAP requirements, DIN 2303 welding standards, or conducting durability and product testing, our experts provide practical guidance to close gaps and embed the right quality practices from the outset.

Gap analysis also underpins our secure supply chain and project support services. For example, when an end user develops new facilities or capabilities, we can support construction companies and their suppliers in meeting the end user’s quality, safety, and security standards. By identifying gaps early and translating requirements into concrete actions, we help organizations reduce risks, improve efficiency, and deliver assured quality throughout the entire lifecycle.

The Global Supply Chain

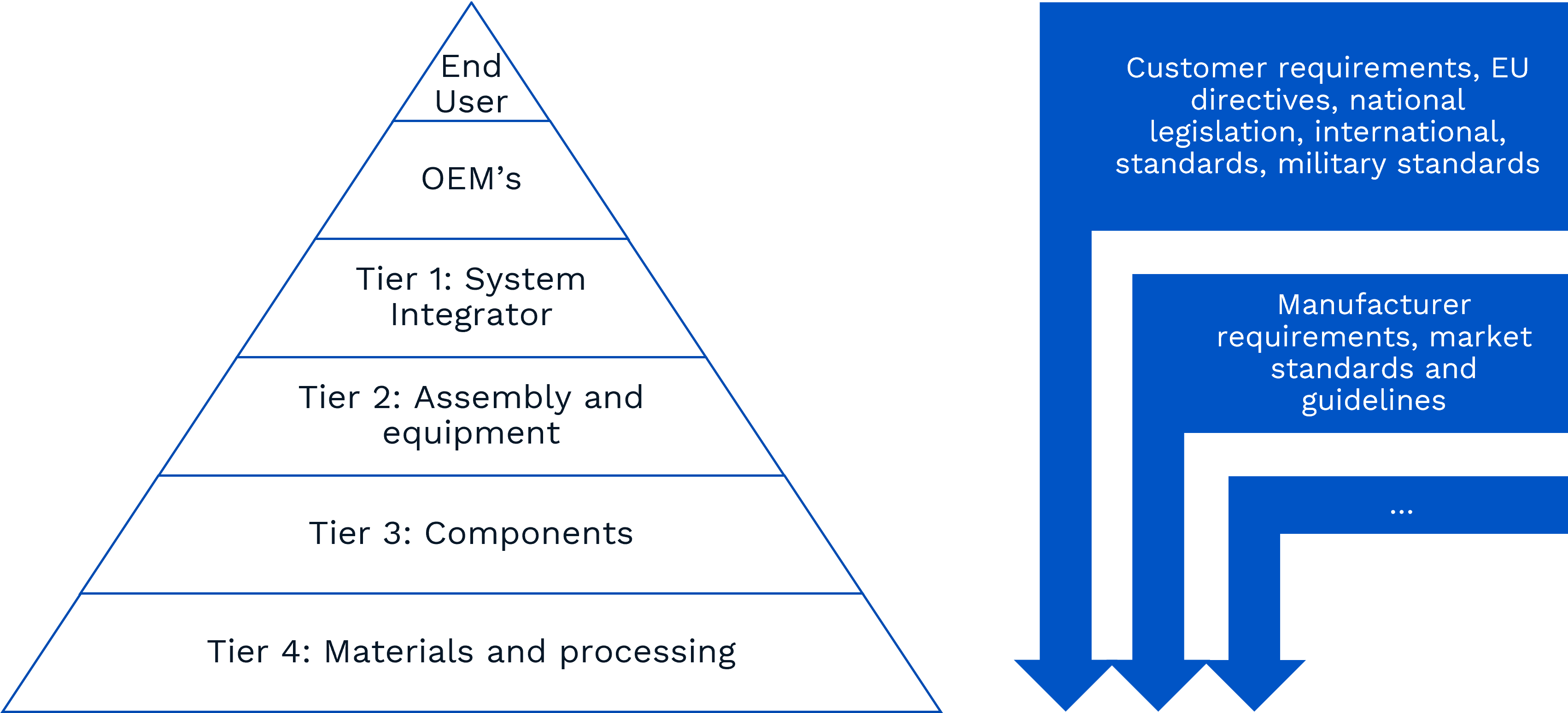

This diagram illustrates how offset clusters function within global supply chains under regulatory frameworks. The supply chain is organised in tiers, from materials and processing through components, assembly, system integration, OEMs, and ultimately the end user. Across all tiers, customer requirements, EU directives, national legislation, international standards, and sector-specific requirements apply and cascade downward through the chain.

This highlights the importance of systematic, end-to-end conformity assessment and compliance management, ensuring that regulatory obligations are consistently met at every level of the global supply chain.

Grow quality with our gap analysis

At Kiwa, we know that quality in the defense sector goes beyond internal processes. It extends across the entire supply chain, from OEMs and their suppliers to contractors delivering critical infrastructure for end users. Our gap analysis services support organizations in strengthening quality at every level, ensuring that products, processes, and partners consistently meet demanding requirements for reliability, compliance, and performance.

We help OEMs improve the quality maturity of their suppliers, particularly when new suppliers are introduced or when specific customer requirements are unfamiliar to them. Whether this involves implementing international standards such as ISO 9001, ISO 27001, NATO AQAP requirements, DIN 2303 welding standards, or conducting durability and product testing, our experts provide practical guidance to close gaps and embed the right quality practices from the outset.

Gap analysis also underpins our secure supply chain and project support services. For example, when an end user develops new facilities or capabilities, we can support construction companies and their suppliers in meeting the end user’s quality, safety, and security standards. By identifying gaps early and translating requirements into concrete actions, we help organizations reduce risks, improve efficiency, and deliver assured quality throughout the entire lifecycle.

Explore our services

Get in touch

At Kiwa, we offer a wide range of testing, inspection, certification, training, and calibration services that are highly relevant to the defense sector. However, many of these services, such as ISO 27001 certification, calibration of measurement devices, and environmental testing, are not limited to a single sector but apply across various industries. This means that while our expertise supports security-related projects, the exact scope and applicability of each service depend on your specific requirements.

If you want to know exactly how Kiwa can support your organization in the defense sector, contact us today—we’re happy to discuss tailored solutions for your needs.